TCC = Torque Converter Clutch

TPS = Throttle Position Sensor

ECT = Engine Coolant Temperature Sensor

VSS = Vehicle Speed Sensor

PSA = Transmission Range Fluid Pressure Switch Assembly

TTS = Transmission Temperature Sensor.

For Holden 4L60-E Transmission:

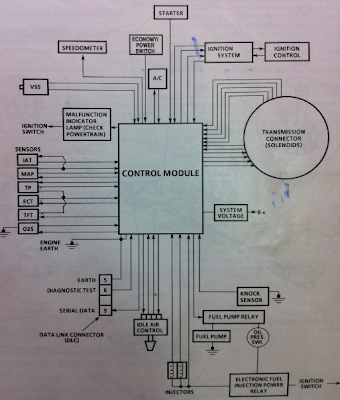

Block Diagram for transmission:

The powertrain control system:

The shift chart:

When the vehicle is shifted into Drive and starts out in first gear, the shift solenoid 1-2 and 2-3 are both ON.

When the vehicle automatically shifts into second gear, the shift solenoid 1-2 is OFF and 2-3 is ON.

When the vehicle automatically shifts into third gear, the shift solenoid 1-2 and 2-3 are both OFF.

When the vehicle automatically shifts into fourth gear, the shift solenoid 1-2 is ON and 2-3 is OFF.

If no solenoids can came ON, the vehicle still can drive but it will stay in third gear, the speed may not go over 40 km/h, and it can climb the hill if the engine is powerful enough,that is the fail safe.

Code:

DTC 24: No vehicle speed signal

This code may caused by faulty ECU, faulty PROM(Programmable read-only memory) or an incorrect PROM,bad connection of the VSS sensor.

For diagnosis the code.

Check the VSS sensor by oscilloscope, if the sensor gives the signal when the wheel is turning, the sensor is working good, then test the continuity between VSS sensor and ECU. The voltage drop should be lower then 0.05V. IF the connection is good, then check the ECU and PROM.

DTC 14: ECT signal voltage is low

This code may caused by faulty ETC sensor, bad connection of ETC sensor.

For diagnosis the code.

Check voltage across the two terminals of the ECT sensor by multimeter, if the voltage decrease as the engine temperature increase, and it about 0.5V after the engine is already warmed up, the ECT sensor and connection are good. If the it is not, test the connection between ECT sensor and ECU and ECT sensor resistance.

On-Car Exercises:

When the O/D is off:

When the O/D is off, the transmission can not goes to 4th gear, because the 4th gear ratio is about 0.8 : 1

When the vehicle at 3rd gear and engine at 2050 RPM. The torque converter clutch lock up solenoid is on to lock up the turbine and flywheel and make the input speed of transmission same as the engine speed.

When O/D is ON:

The vehicle can shift to 4th gear now and torque converter clutch lock up solenoid is on at 1600RPM at 4th gear.

When the driver apply the feet on the brake pedal and slow down the vehicle, the torque converter clutch will disengage, flywheel and turbine are disconnected.

The chart: