Zirconia type: create its own voltage 0.1-1V

Titania type: use reference voltage. O2 changes the resistance of the sensor.

Wideband type: gives signal voltage to ECU to let it know rich or lean, and measure the current to know how rich or lean it is.

Locate oxygen sensor

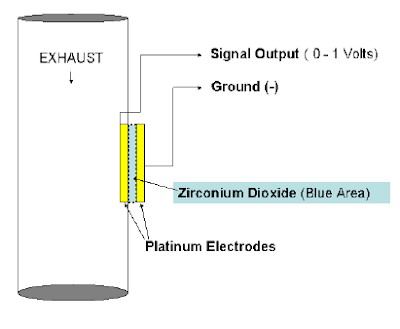

The Oxygen sensor locate on the exhaust pipe before catalytic converter. Some vehicles have 2 oxygen sensors one before and one after the catalytic converter.

This O2 sensor is zirconia switching sensor and it has 3 wires, two white wires are heater ground and positive, and black wire is signal out.

Back probe the oxygen signal wire and connect to an oscilloscope.

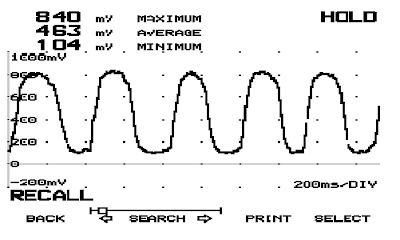

Watch and record oxygen signal pattern at 2500rpm. Let the engine warm up and enter closed loop so you see a normal cycling pattern.

The pattern:

Highest Voltage | 0.9v |

Lowest Voltage | 0.02v |

Average Voltage | 0.6v |

Cross Counts | 5 |

This pattern is not cycling normally, but it still works fine. Because the ECU is aftermarket not the original one and the wiring in different way.

The normal cycling close loop pattern:

The engine run rich to let catalytic converter clean up NOx by using CO.

The engine run lean to let catalytic converter clean up HC and CO by using O2.

Watch and record oxygen signal pattern at idle rpm. Let the engine warm up and enter closed loop so you see a normal cycling pattern.

The pattern:

| Highest Voltage | 0.021v |

Lowest Voltage | 0.014v |

Average Voltage | 0.017v |

Cross Counts | 0 |

This pattern is not cycling normally. Because the ECU is aftermarket not the original one and the wiring in different way. The normal cycling pattern should be a line about 0.45v

Make the oxygen sensor go rich by accelerating once or twice. The signal should go over 0.85v

The pattern:

The highest voltage is 0.9V

The pattern still not normally, but we still can find out when engine run rich, the signal voltage is over 0.45V

Make this oxygen sensor go lean by doing a sudden deceleration. Gently run the rpm up to about 3,000, and let the rpm drop suddenly. The fuel system should make the system go lean on deceleration. The signal should go below 0.2V.

The pattern:

The lowest voltage goes close to 0v

The pattern seems normal because when the engine go lean, O2 sensor signal lower the 0.45V. For normal pattern, the voltage should go back to 0.45v after reach close to 0v.

Measure the response time of the sensor. Sudden acceleration, freeze the pattern, and measure how long it took the sensor to go from lean to rich.

The pattern:

The sensor took under 100ms to go from lean to rich

The normal Zirconium oxygen sensor:

When engine is running,there is O2 in the exhaust pipe, O2 sensor compare the O2 in the pipe and O2 outside air, different amount of O2 in the pipe and outside air create the pressure to let O++ flow through. O++ attract the electrons and create the signal voltage of O2 sensor.

The perfect air/fuel ratio for petrol is 14.7:1 Lambda = 1

When engine runs rich. Less O2 available than demand, so Lambda < 1, signal voltage > 0.45v

When engine runs lean. More O2 available than demand, so Lambda > 1, signal voltage < 0.45v

No comments:

Post a Comment